What is the best way to reduce the likelihood of equipment failing? Preventive maintenance. It is tough, if not impossible, to commit already-strained IT resources to work on mobile computer carts or Workstation on Wheels (WOWs) when an issue arises, let alone plan preventive maintenance. A Preventive Maintenance (PM) project has many benefits though. It is an investment that can alleviate workstation downtime, reduce the number of IT help desk tickets, and elongate the life of the cart.

Convergint Innovative Medical has a team of manufacturer-certified service technicians located throughout the U.S. that come onsite with a spare parts kit and customer-specified upgrade parts needed to replace worn parts before they fail. The project includes a top-to-bottom review of carts to tighten screws/bolts, replace worn/broken parts, manage cables, wipe down the cart for an aesthetic improvement, and thoroughly clean the power system.

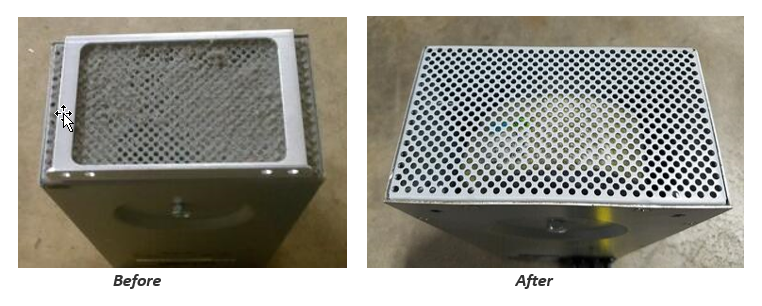

Cleaning the power system has always been part of the Convergint Innovative Medical plan but now it is also the recommendation of the FDA per their news release, December 2016, for reducing the likelihood of a Lithium battery and power inverter overheating event. Cleaning the dust from the inverter and air filter not only reduces the likelihood of an overheating issue, but it also prolongs the life of the entire power system by allowing it to run at a cooler temperature with proper ventilation. Dust buildup is the main cause of overheating and premature failure of the power inverter and battery, two of the most expensive components of the cart.

Replacing worn or broken parts increases workstation availability when a clinician needs it which in turn increases clinician efficiency and satisfaction when time is not spent searching for a functional cart or submitting a service request. It also reduces the number of help desk tickets, alleviating strain on the IT staff and need for additional resources.

Having carts tuned up keeps them looking and running well. The Convergint Innovative Medical service team has customer carts that are still in service after nearly ten years. By simply performing regular maintenance and care on these carts they still perform at optimal levels and meet 24/7 clinical demands.

Our cart projects can also include swapping out defective keyboards, mice, barcode scanners, or upgrading to a larger size display. Because our technicians get their hands on each cart at a facility, it is an optimal time to perform any upgrades or parts replacement that had been put off. We have solutions for upgrading to dual displays or adding storage drawers. The Convergint Innovative Medical Service Team can perform as much or little work to the cart fleet as desired. Call us today to find out more about our P.M. Service Program, and how we can help you extend the life of your carts! 800-968-3135.