What happens after you send in a PO for an order to IMS? Our precise process and detailed attention comes into play. The PO takes a journey of checks and double checks:

- When the PO is received the individual that quoted the product will review and make sure everything is correct.

- The PO then transitions into an order and is entered into our ordering system.

- The order is reviewed once again to make sure it matches our conversation with the customer on their design and clinical needs.

- We verify shipping information including address and dock information.

- Now the order is finally ready to be sent to the manufacturer to get on their production schedule.

- Once they receive the order, we will receive a detailed order confirmation and an estimated ship date.

- Product details are double checked on the confirmation to ensure it matches the PO and the ship date is verified to insure it meets the customer’s needs for shipping.

Our goal is always customer focused and we strive to make sure your product arrives within an acceptable time frame. At this point, we will continue to monitor the manufacturer’s production schedule to make sure everything stays on schedule and nothing needs to be changed. Once your product is shipped, the process isn’t over. We continue our communication about the product – did it arrive in good condition? Does it need any extra instruction for set up? Months later we will check in to make sure the product is still meeting your original needs. We even follow up years later to make sure the quality has stood the test of time.

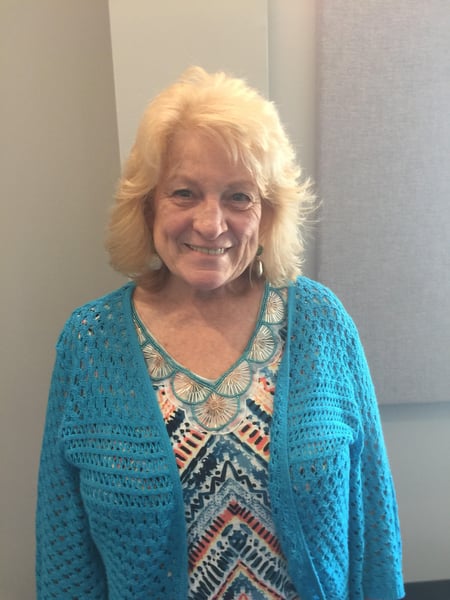

One of the IMS team members, Marlene Feistamel,  makes sure the wheels turn smoothly for IMS when placing your order. She has worked for IMS for 14 years and brings a lot of joy to our organization! Her commitment to our customers to make sure we deliver what we say is unparalleled. About Marlene:

makes sure the wheels turn smoothly for IMS when placing your order. She has worked for IMS for 14 years and brings a lot of joy to our organization! Her commitment to our customers to make sure we deliver what we say is unparalleled. About Marlene:

What is your Job title and how has your job changed or evolved since working here? Materials Management Coordinator - I have seen many changes over the years. One big change is how a shipment is processed. Common carriers have gone from handwriting shipping documents to web-based entry. IMS utilizes a program that automatically enters the shipping information from our sales order, records tracking number and puts the freight charge direct onto our invoice as a line item. In addition, we used to hand write all serial numbers on items that were being received and shipped, then we manually typed the numbers into our system. Today all shipping and receiving is scanned into the system eliminating entry errors.

What is the most challenging part of your job? Time management. Everything I do is a result of something else going on in the company. Therefore, setting my own schedule never happens.

What is special about IMS? Or what do we offer our customers that other companies don’t? IMS has true team work and accountability. We are caring individuals, who work together for the common goal of customer satisfaction.

What do you enjoy doing when you are not working? I enjoy spending time with my family, serving the community with my church, mentoring college aged girls, and card making.